-

StevenCHN-TOP ให้บริการที่ดีมากและผลิตภัณฑ์ช่วยเราได้มาก

StevenCHN-TOP ให้บริการที่ดีมากและผลิตภัณฑ์ช่วยเราได้มาก -

เอสเอ็น ชาร์มาเครื่อง CHN-TOP ช่วยฉันปรับปรุงการแสดงผลสำหรับเครื่องจีน

เอสเอ็น ชาร์มาเครื่อง CHN-TOP ช่วยฉันปรับปรุงการแสดงผลสำหรับเครื่องจีน -

ไมค์สินค้าที่ดีที่สุดในราคาที่ดีที่สุด CHN-TOP ทำได้ดีมาก!

ไมค์สินค้าที่ดีที่สุดในราคาที่ดีที่สุด CHN-TOP ทำได้ดีมาก!

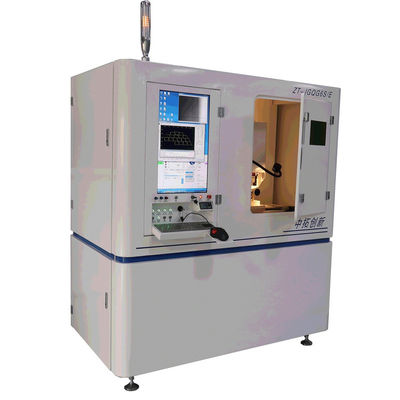

เครื่องตัดไฟเบอร์เลเซอร์ CNC ระบบควบคุม HE MOSS สำหรับตัดสแตนเลสหนา 5 มม. ขีดจำกัดความหนา 380V/50Hz แรงดันไฟฟ้า

| Maximum Speed | 100m/min | Control System | CNC Controller |

|---|---|---|---|

| Cutting Thickness Limit | 5mm Stainless Steel | Outline Size | 4450mm X 2450mm X 1800mm |

| Material | PDC | Weight | 700kg |

| Cooling Mode | Water Cooling | Configuration | 3-axis |

| เน้น | เครื่องตัดไฟเบอร์เลเซอร์ CNC สำหรับสแตนเลสหนา 5 มม.,เครื่องตัดไฟเบอร์เลเซอร์ CNC 380V สำหรับโลหะ,ระบบตัดเลเซอร์ HE MOSS พร้อมการรับประกัน |

||

รายละเอียดสินค้า:

เครื่องตัดเลเซอร์ไฟเบอร์ CNC เป็นเครื่องตัดเลเซอร์เพชรขั้นสูงและมีประสิทธิภาพสูง ออกแบบมาเพื่อตอบสนองความต้องการของการผลิตในอุตสาหกรรมสมัยใหม่ ด้วยการใช้เทคโนโลยีเลเซอร์ไฟเบอร์ที่ทันสมัย เครื่องนี้ให้ความแม่นยำ ความเร็ว และความสามารถรอบด้าน ทำให้เป็นตัวเลือกที่เหมาะสำหรับการใช้งานต่างๆ ในการแปรรูปและผลิตโลหะ การรวมการกำหนดค่า 3 แกนช่วยให้มั่นใจได้ถึงการเคลื่อนไหวที่ราบรื่นและแม่นยำ ทำให้สามารถทำงานตัดที่ซับซ้อนและมีรายละเอียดได้อย่างง่ายดาย

หนึ่งในคุณสมบัติเด่นของเครื่องตัดเลเซอร์ไฟเบอร์นี้คือความเข้ากันได้กับโหมดการเขียนโปรแกรมการวาดภาพหลายแบบ รองรับการนำเข้าไฟล์รูปแบบ AI, DWG, PLT และ DXF โดยตรง ซึ่งช่วยลดความซับซ้อนของเวิร์กโฟลว์ตั้งแต่การออกแบบไปจนถึงการผลิตอย่างมาก ความยืดหยุ่นนี้ช่วยให้ผู้ปฏิบัติงานสามารถทำงานกับซอฟต์แวร์การออกแบบที่หลากหลาย ทำให้กระบวนการถ่ายโอนการออกแบบดิจิทัลไปยังการตัดจริงง่ายขึ้น ความสามารถในการจัดการรูปแบบไฟล์กราฟิกเวกเตอร์และ CAD ทั่วไปเหล่านี้ทำให้เครื่องสามารถปรับตัวเข้ากับสภาพแวดล้อมทางอุตสาหกรรมและความต้องการของโครงการต่างๆ ได้อย่างสูง

เครื่องทำงานที่แรงดันไฟฟ้ามาตรฐาน 380V/50Hz ทำให้มั่นใจได้ถึงแหล่งจ่ายไฟที่เชื่อถือได้และเสถียร เหมาะสำหรับการตั้งค่าทางอุตสาหกรรม ข้อมูลจำเพาะแรงดันไฟฟ้านี้ช่วยให้เครื่องตัดเลเซอร์เพชรรักษาสมรรถนะที่สม่ำเสมอในระหว่างการใช้งานเป็นเวลานาน ลดเวลาหยุดทำงานและเพิ่มผลผลิต การกำหนดค่าทางไฟฟ้าที่แข็งแกร่งรองรับการทำงานตัดที่มีความแม่นยำสูงซึ่งเทคโนโลยีเลเซอร์ไฟเบอร์ต้องการ ทำให้มั่นใจได้ว่าการตัดแต่ละครั้งจะสะอาดและแม่นยำ

ในแง่ของความเร็ว เครื่องตัดเลเซอร์ไฟเบอร์ CNC มีความเร็วสูงสุด 100 เมตรต่อนาที ความสามารถในการตัดที่รวดเร็วนี้ช่วยเพิ่มปริมาณงานได้อย่างมาก ทำให้ผู้ผลิตสามารถทำงานจำนวนมากให้เสร็จสิ้นได้ในกรอบเวลาที่สั้นลงโดยไม่กระทบต่อคุณภาพ การทำงานด้วยความเร็วสูง รวมกับความแม่นยำของระบบ 3 แกน ทำให้สามารถตัดการออกแบบที่ซับซ้อนและรูปร่างที่ซับซ้อนได้อย่างรวดเร็วและมีประสิทธิภาพ ทำให้เป็นเครื่องมืออเนกประสงค์สำหรับอุตสาหกรรมต่างๆ ตั้งแต่อุตสาหกรรมยานยนต์ไปจนถึงการบินและอวกาศและการผลิตเครื่องประดับ

สร้างขึ้นโดยใช้วัสดุ PDC (Polycrystalline Diamond Composite) ระดับพรีเมียม เครื่องนี้มีความทนทานและทนต่อการสึกหรอที่เพิ่มขึ้น ทางเลือกของวัสดุนี้มีส่วนช่วยให้อายุการใช้งานของส่วนประกอบการตัดยาวนานขึ้น ทำให้มั่นใจได้ถึงประสิทธิภาพที่สม่ำเสมอเมื่อเวลาผ่านไปและลดต้นทุนการบำรุงรักษา การใช้ PDC ในเครื่องตัดเลเซอร์เพชรไม่เพียงแต่ช่วยปรับปรุงอายุการใช้งานเท่านั้น แต่ยังรองรับการตัดที่มีความแม่นยำสูงโดยการรักษาความคมชัดและความสมบูรณ์ของขอบตัดในระหว่างการใช้งานเป็นเวลานาน

แหล่งกำเนิดเลเซอร์ขั้นสูงของเครื่องตัดเลเซอร์ไฟเบอร์ให้คุณภาพลำแสงที่เหนือกว่าและความหนาแน่นของพลังงานสูง ซึ่งมีความสำคัญอย่างยิ่งในการตัดละเอียดโดยมีโซนที่ได้รับผลกระทบจากความร้อนน้อยที่สุด สิ่งนี้ช่วยลดการบิดเบือนของวัสดุและทำให้มั่นใจได้ถึงการตกแต่งที่มีคุณภาพสูงบนโลหะและโลหะผสมต่างๆ การควบคุมที่แม่นยำซึ่งระบบ CNC มอบให้ช่วยให้สามารถดำเนินการรูปแบบที่ซับซ้อนและการออกแบบที่มีรายละเอียดได้อย่างสมบูรณ์แบบ ทำให้เหมาะสำหรับอุตสาหกรรมที่ต้องการงานฝีมือที่พิถีพิถัน

นอกจากนี้ เครื่องตัดเลเซอร์เพชรนี้ใช้งานง่ายด้วยอินเทอร์เฟซที่ใช้งานง่ายซึ่งช่วยลดความซับซ้อนของกระบวนการเขียนโปรแกรมและการทำงาน การรวมการสนับสนุนไฟล์ AI และ CAD หมายความว่าผู้ใช้สามารถตั้งค่างานได้อย่างรวดเร็วโดยไม่จำเป็นต้องมีการฝึกอบรมที่ครอบคลุม ลดเส้นโค้งการเรียนรู้และเพิ่มประสิทธิภาพในการดำเนินงาน โครงสร้างที่แข็งแกร่งและคุณสมบัติขั้นสูงของเครื่องทำให้เป็นพันธมิตรที่เชื่อถือได้สำหรับธุรกิจที่มุ่งหวังที่จะเพิ่มขีดความสามารถในการผลิตด้วยเทคโนโลยีการตัดด้วยเลเซอร์สมัยใหม่

โดยสรุป เครื่องตัดเลเซอร์ไฟเบอร์ CNC เป็นเครื่องตัดเลเซอร์ไฟเบอร์ที่ทันสมัยซึ่งผสมผสานความแม่นยำสูง ความเร็ว และความสามารถรอบด้าน ด้วยการกำหนดค่า 3 แกน ความเข้ากันได้กับรูปแบบไฟล์การออกแบบทั่วไป เช่น AI, DWG, PLT และ DXF และข้อกำหนดด้านพลังงานที่แข็งแกร่ง 380V/50Hz ได้รับการออกแบบมาเพื่อจัดการกับการใช้งานในอุตสาหกรรมที่ต้องการได้อย่างมีประสิทธิภาพ การใช้วัสดุ PDC ที่ทนทานช่วยเพิ่มประสิทธิภาพและอายุการใช้งาน ไม่ว่าคุณกำลังมองหาการปรับปรุงความเร็วในการผลิตหรือบรรลุการออกแบบการตัดที่ซับซ้อน เครื่องตัดเลเซอร์เพชรนี้มีโซลูชันที่ครอบคลุมซึ่งปรับให้เหมาะกับความต้องการในการผลิตที่หลากหลาย

พารามิเตอร์ทางเทคนิค:

| แรงดันไฟฟ้า | 380V/50Hz |

| น้ำหนัก | 700kg |

| ยี่ห้อแหล่งกำเนิดเลเซอร์ | Trumpf |

| ขีดจำกัดความหนาในการตัด | สแตนเลส 5 มม. |

| พื้นที่ทำงาน | 3*1.5 ม. |

| ระบบควบคุม | ตัวควบคุม CNC |

| ความเร็วสูงสุด | 100m/min |

| แกนหมุน | การระบายความร้อนด้วยอากาศ |

| โหมดระบายความร้อน | การระบายความร้อนด้วยน้ำ |

| การกำหนดค่า | 3 แกน |

การใช้งาน:

เครื่องตัดเลเซอร์ไฟเบอร์ CTSTC ZT-JGQG6S/E เป็นเครื่อง CNC เลเซอร์ไฟเบอร์ที่มีประสิทธิภาพสูงและมีความหลากหลายสูง ออกแบบมาสำหรับการตัดที่มีความแม่นยำในการใช้งานทางอุตสาหกรรมต่างๆ ได้รับการรับรองด้วย CE เครื่องตัดเลเซอร์ไฟเบอร์นี้ช่วยให้มั่นใจได้ถึงการปฏิบัติตามมาตรฐานความปลอดภัยและคุณภาพระดับสากล ทำให้เป็นตัวเลือกที่เชื่อถือได้สำหรับผู้ผลิตที่ต้องการประสิทธิภาพสูงสุด ด้วยปริมาณการสั่งซื้อขั้นต่ำเพียงหนึ่งหน่วย ธุรกิจต่างๆ สามารถรวมอุปกรณ์ขั้นสูงนี้เข้ากับสายการผลิตได้อย่างง่ายดาย

เหมาะสำหรับการตัดวัสดุ PDC เครื่องตัดเลเซอร์ไฟเบอร์ CTSTC มีโครงสร้างที่แข็งแกร่ง 700 กก. และใช้โหมดการระบายความร้อนด้วยน้ำที่มีประสิทธิภาพเพื่อรักษาระดับอุณหภูมิการทำงานที่เหมาะสมที่สุดในระหว่างการใช้งานเป็นเวลานาน ระบบควบคุม CNC ช่วยให้สามารถควบคุมการตัดได้อย่างราบรื่นและแม่นยำ ช่วยเพิ่มผลผลิตและความแม่นยำ

เครื่อง CNC เลเซอร์ไฟเบอร์นี้รองรับโหมดการเขียนโปรแกรมการวาดภาพหลายแบบ รวมถึงการนำเข้ารูปแบบ AI, DWG, PLT และ DXF โดยตรง ทำให้ผู้ใช้สามารถทำงานกับไฟล์การออกแบบที่หลากหลายได้โดยไม่จำเป็นต้องแปลง สิ่งนี้ทำให้เหมาะสำหรับอุตสาหกรรมต่างๆ เช่น การผลิตยานยนต์ การผลิตโลหะ การบินและอวกาศ อิเล็กทรอนิกส์ และการผลิตป้ายแบบกำหนดเอง ซึ่งจำเป็นต้องมีการตัดที่ซับซ้อนและมีความแม่นยำสูง

เครื่องตัดเลเซอร์ไฟเบอร์ CTSTC บรรจุในกล่องไม้อัดอย่างปลอดภัยเพื่อให้แน่ใจว่าการจัดส่งปลอดภัยและมาถึงภายใน 45-60 วันหลังจากยืนยันการสั่งซื้อ เงื่อนไขการชำระเงินมีความยืดหยุ่นด้วยตัวเลือก TT ที่มีอยู่ อำนวยความสะดวกในกระบวนการทำธุรกรรมที่ราบรื่น เมื่อพิจารณาจากเทคโนโลยีขั้นสูง ใช้งานง่าย และความทนทาน เครื่องตัดเลเซอร์ไฟเบอร์นี้จึงเหมาะสำหรับเวิร์กช็อป โรงงาน และโรงงานผลิตที่มุ่งหวังที่จะเพิ่มขีดความสามารถในการตัดและประสิทธิภาพ

ไม่ว่าจะตัดแผ่นโลหะบางๆ รูปแบบที่ซับซ้อน หรือส่วนประกอบที่ซับซ้อน รุ่น ZT-JGQG6S/E โดดเด่นในฐานะโซลูชันที่มีประสิทธิภาพซึ่งตอบสนองความต้องการที่หลากหลายของสภาพแวดล้อมการผลิตสมัยใหม่ การควบคุมที่แม่นยำ ระบบระบายความร้อนที่มีประสิทธิภาพ และความเข้ากันได้ที่หลากหลายกับรูปแบบการออกแบบทำให้เป็นสินทรัพย์ที่มีค่าสำหรับธุรกิจที่ต้องการปรับปรุงการดำเนินงานการตัดด้วยเลเซอร์ไฟเบอร์

การสนับสนุนและบริการ:

เครื่องตัดเลเซอร์ไฟเบอร์ CNC ของเราได้รับการออกแบบมาเพื่อให้ความแม่นยำและประสิทธิภาพสูงสำหรับการใช้งานตัดโลหะต่างๆ เพื่อให้มั่นใจถึงประสิทธิภาพสูงสุดและอายุการใช้งานที่ยาวนานของเครื่องของคุณ เราให้บริการด้านเทคนิคและบริการที่ครอบคลุม

การสนับสนุนด้านเทคนิค:

ทีมงานด้านเทคนิคที่มีประสบการณ์ของเราพร้อมให้ความช่วยเหลือคุณในการติดตั้ง การตั้งค่า และการแก้ไขปัญหา เราให้คำแนะนำเกี่ยวกับการกำหนดค่าซอฟต์แวร์ การสอบเทียบเครื่องจักร และขั้นตอนการบำรุงรักษา เพื่อช่วยให้คุณได้ผลลัพธ์การตัดที่ดีที่สุด

บริการบำรุงรักษา:

การบำรุงรักษาตามปกติมีความสำคัญอย่างยิ่งต่อการรักษาความแม่นยำและความเสถียรในการทำงานของเครื่อง เราให้บริการบำรุงรักษาตามกำหนดเวลา รวมถึงการทำความสะอาด การหล่อลื่น และการตรวจสอบส่วนประกอบสำคัญ เพื่อป้องกันเวลาหยุดทำงานที่ไม่คาดคิด

การฝึกอบรมและเอกสารประกอบ:

เรามีคู่มือผู้ใช้โดยละเอียดและเซสชันการฝึกอบรมเพื่อให้แน่ใจว่าผู้ปฏิบัติงานของคุณมีความรู้ความเข้าใจในขั้นตอนการทำงานและความปลอดภัยของเครื่องตัดเลเซอร์ไฟเบอร์ CNC การฝึกอบรมที่เหมาะสมช่วยเพิ่มผลผลิตและลดข้อผิดพลาดในการดำเนินงาน

การอัปเกรดและอะไหล่:

เพื่อให้เครื่องของคุณทันสมัยอยู่เสมอด้วยเทคโนโลยีและมาตรฐานประสิทธิภาพล่าสุด เรามีตัวเลือกการอัปเกรดและอะไหล่แท้ การใช้ชิ้นส่วนที่ได้รับอนุญาตช่วยให้มั่นใจได้ถึงความเข้ากันได้และรักษาการรับประกันของเครื่อง

การรับประกันและการซ่อมแซม:

เครื่องตัดเลเซอร์ไฟเบอร์ CNC มาพร้อมกับการรับประกันที่ครอบคลุมซึ่งครอบคลุมข้อบกพร่องในการผลิตและความล้มเหลวทางกลไก ในกรณีที่มีปัญหาใดๆ ทีมบริการของเราจะแก้ไขการซ่อมแซมทันทีเพื่อลดเวลาหยุดทำงาน

สำหรับคำถามทางเทคนิคหรือคำขอรับบริการ โปรดดูแหล่งข้อมูลสนับสนุนที่มาพร้อมกับเครื่องของคุณ หรือเยี่ยมชมเว็บไซต์ทางการของเราเพื่อขอความช่วยเหลือเพิ่มเติม